It’s a kind of subsumption architecture model.

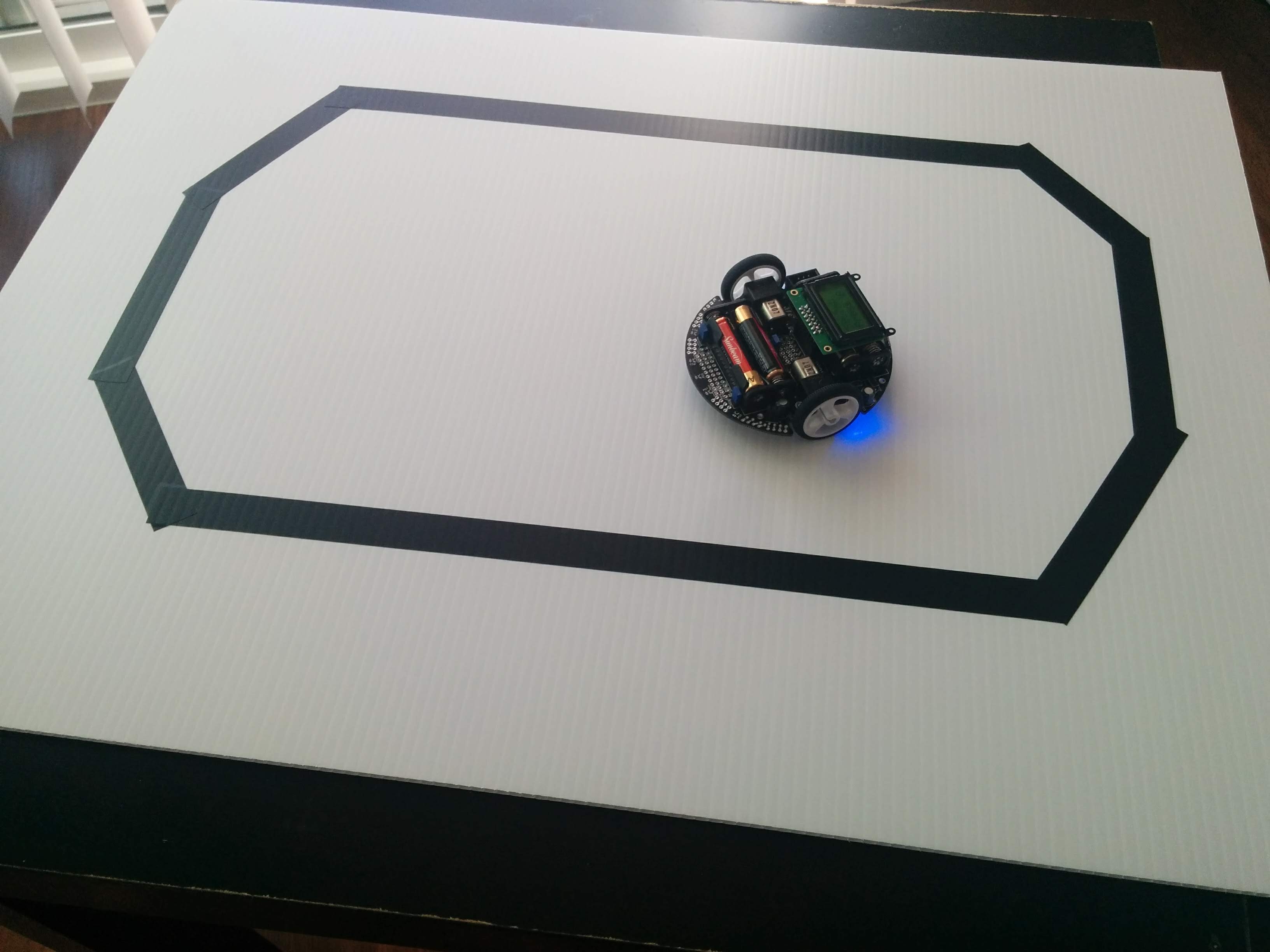

Looks smart like Roomba. But actually, really simple system.

Environment

- Ubuntu 16.04

- Pololu 3pi Robot (ATmega328P)

C code

Result

I assume that it can be a home cleaning robot.

It’s a kind of subsumption architecture model.

Looks smart like Roomba. But actually, really simple system.

I assume that it can be a home cleaning robot.